From Outages to Power Quality Issues: How We Ensured Seamless Switching and Protected Critical Loads

In our facility, every second of downtime counts. We manage multiple production lines, sensitive control systems, and a variety of auxiliary equipment that must stay operational. Like most industrial setups in India, we rely on two primary power sources: the Electricity Board (EB) supply and a Diesel Generator (DG) backup.

One of the biggest challenges we’ve faced over the years is ensuring a smooth and safe transition from EB to DG, especially during sudden power cuts. In the past, these transitions were a source of stress — trips, voltage dips, overloaded generators, and even equipment damage. Today, we’ve come a long way in streamlining this process, and this article captures our learning, so other maintenance teams can benefit from it.

Why EB to DG Switching Matters So Much

We’ve had days when a sudden EB outage caused:

- DG starting delays, leading to production stoppage.

- All loads coming online together, overloading the generator.

- Voltage and frequency fluctuations damaging VFDs and PLC power supplies.

- Safety risks when critical loads like ventilation or fire pumps weren’t prioritized.

Each of these incidents cost us time, money, and sometimes even our hard-earned reputation with clients. That’s why we decided to take a systematic approach.

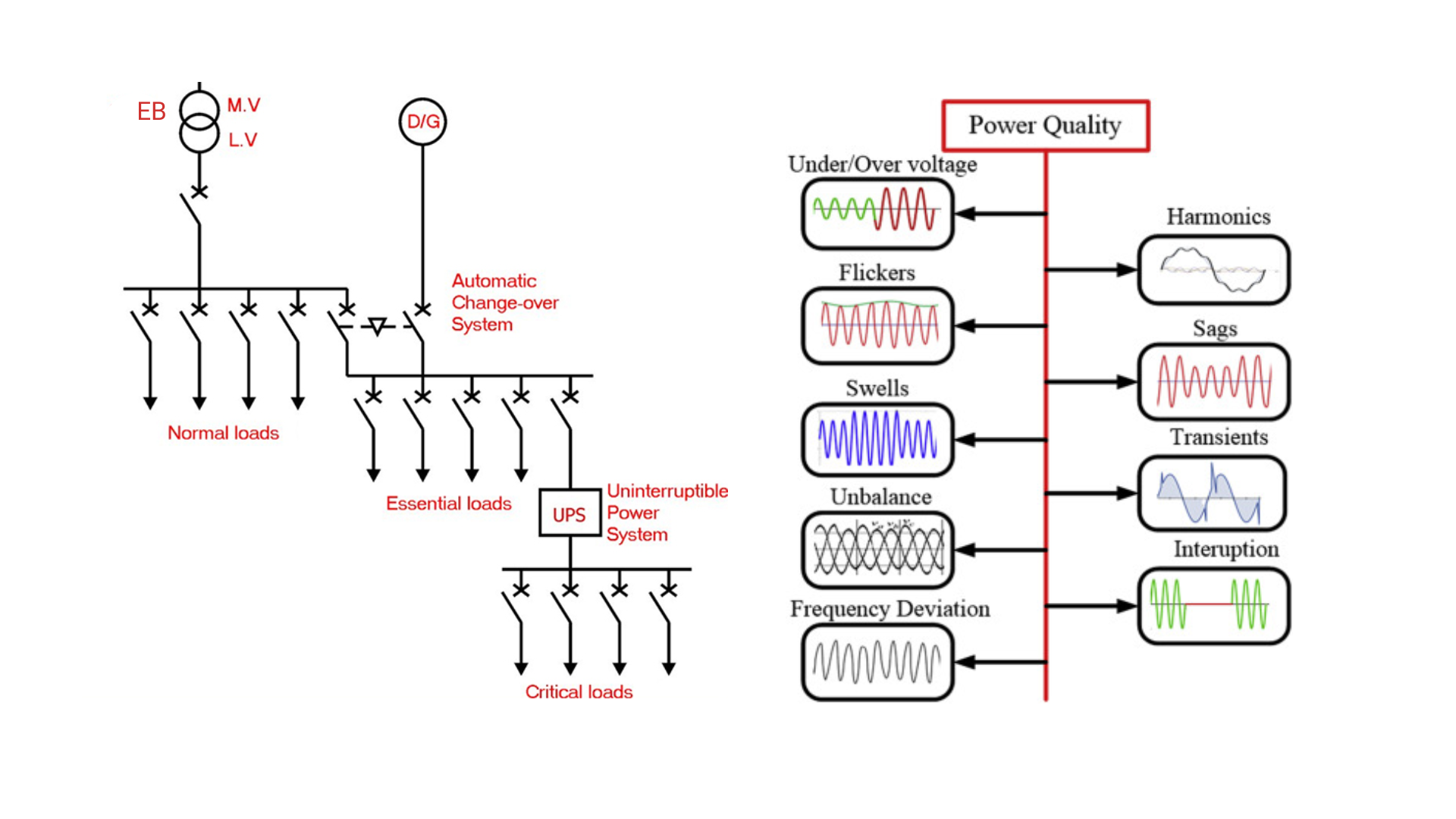

Step 1 – Understanding Our Loads

The first thing we learned: not all loads are equal.

We mapped our loads into:

- Critical Loads: Safety systems (fire pumps, emergency lighting, communication), essential process equipment, control systems, and IT servers.

- Non-Critical Loads: HVAC for comfort areas, some lighting circuits, non-essential conveyors or pumps.

- Deferrable Loads: Equipment that can wait until EB power returns or until the DG is stable.

This mapping was done before we even looked at any switching device. Without it, no amount of automation will solve the problem.

Step 2 – Choosing the Right Switching Approach

We evaluated different methods and realized there’s no “one-size-fits-all” solution.

- Automatic Transfer Switch (ATS)

Best for when we need instant, unattended, and reliable source switching.- Detects EB failure and starts the DG automatically.

- Switches the load seamlessly without operator intervention.

- Ideal for large incomers feeding multiple circuits at once.

- Automatic Changeover with Current Limiter (ACCL)

Perfect for load prioritization when DG capacity is lower than EB capacity.- Lets us limit DG current so only critical loads run during backup.

- Protects the generator from overload.

- Works well for commercial and mixed-load facilities.

- Manual Changeover with Sequenced Start

We still use this in some areas where cost is a constraint and loads are less critical. Operators are trained to bring loads online in stages.

Step 3 – Sequencing the Transition

Even with automation, sequencing is important.

- Critical loads first — DG takes these as soon as it’s up.

- Secondary loads after stabilization — usually after 30–60 seconds.

- Large motor loads last — brought online with soft starters or VFD ramp-up to avoid sudden inrush.

We built this logic into our ATS/ACCL programming to ensure it happens every time.

Step 4 – Protecting Equipment During the Transition

One thing we learned quickly — switching without monitoring is risky. We added:

- Voltage & Frequency Monitoring Relays to prevent supply to loads until parameters are within limits.

- Phase Sequence Protection to ensure motor-driven loads don’t run in reverse.

- Under/Over Voltage Cutoffs to prevent damage to sensitive electronics.

These may seem minor, but they’ve saved us from costly failures more than once.

Step 5 – Testing and Training

We don’t wait for a real outage to test our system. Every month:

- We simulate an EB failure and record DG start-up time.

- Verify sequencing works as programmed.

- Check alarms, communication, and operator response time.

- Ensure our logbook captures all events for analysis.

We also train our operators on manual fallback procedures, just in case automation fails.

Step 6 – Measuring the Benefits

Since implementing our planned EB to DG transition system:

- Overload trips during changeover have reduced to almost zero.

- DG fuel efficiency has improved as unnecessary loads remain offline.

- Downtime from power cuts has dropped significantly.

- Equipment failure due to switching surges is rare.

Key Takeaways for Other Maintenance Teams

If you’re planning or upgrading your EB to DG switching, here’s our checklist:

- Map your loads into critical, non-critical, and deferrable.

- Decide between ATS, ACCL, or a hybrid system.

- Build sequencing into your logic.

- Add voltage and frequency monitoring protection.

- Test regularly — not just when the power fails.

- Keep your SOPs updated and train your team.

Final Thought

In our experience, a well-planned EB to DG transition isn’t just about having the right hardware. It’s about understanding your loads, anticipating real-world problems, and putting in place a system that works every single time — with or without operator presence. If you get this right, your facility will not only run smoother during outages but will also protect its assets, save on fuel, and avoid costly downtime.