Electrical Anomaly Monitoring: Proactive Detection and Prevention of Electrical Fire Risk

Electrical fires rarely begin with a dramatic fault event. They begin quietly.

Long before insulation burns or smoke becomes visible, electrical systems often experience subtle deviations from their engineered operating state....

Energy Governance at Multi-Store Retail: How Continuous Electrical Monitoring Reinforced Energy Budget Optimization and Operational Safety

Managing energy across a large retail network is fundamentally different from managing it at a single site. At scale, even small inefficiencies repeat across hundreds of locations, turning minor issues...

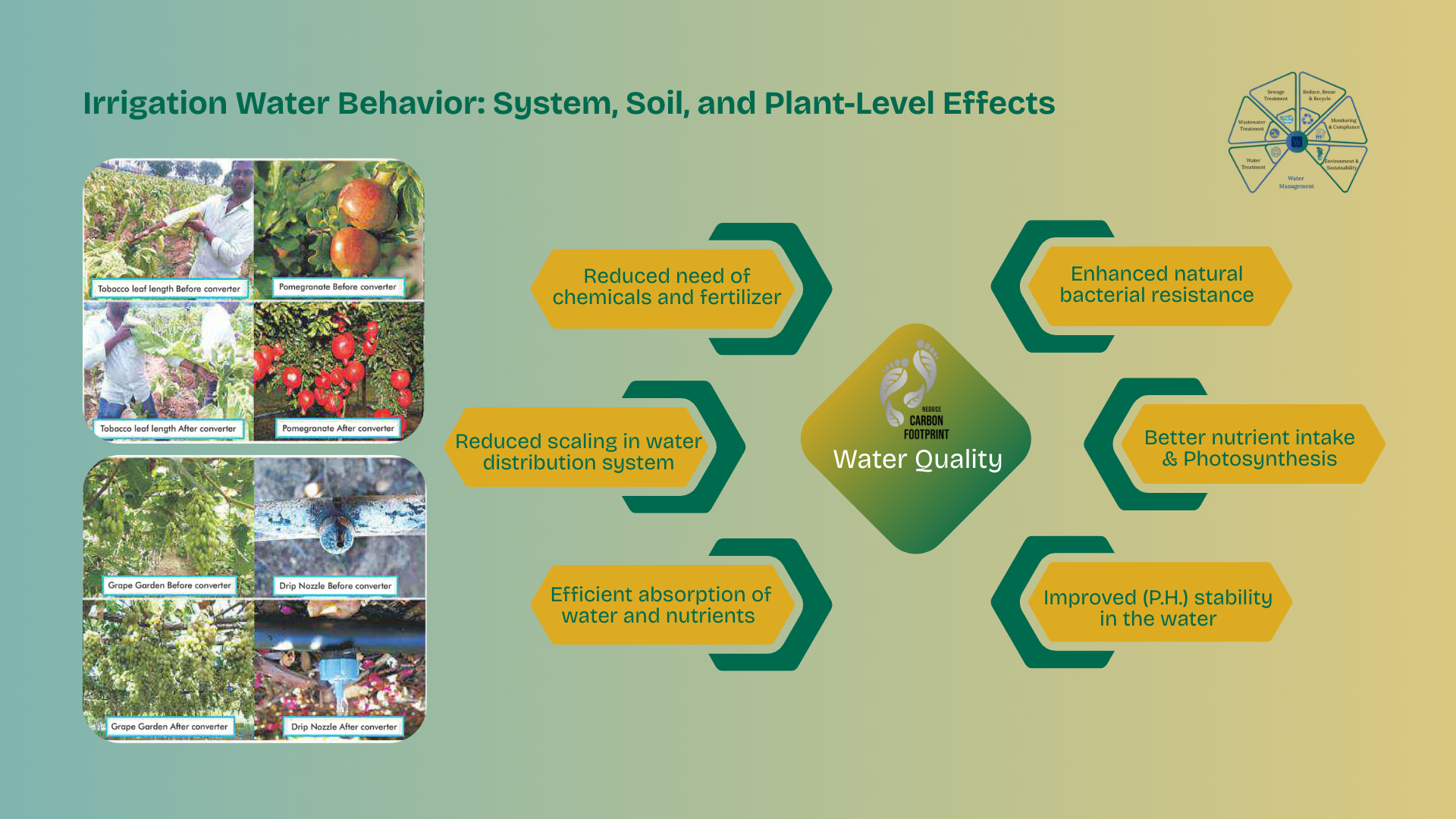

Irrigation Water Behavior: Its Impact on System Performance, Soil Moisture, and Plant Function

Agriculture today faces one of its most pressing challenges: achieving ever-higher productivity with limited and deteriorating water resources. In this context, irrigation infrastructure and water quality become strategic determinants of...

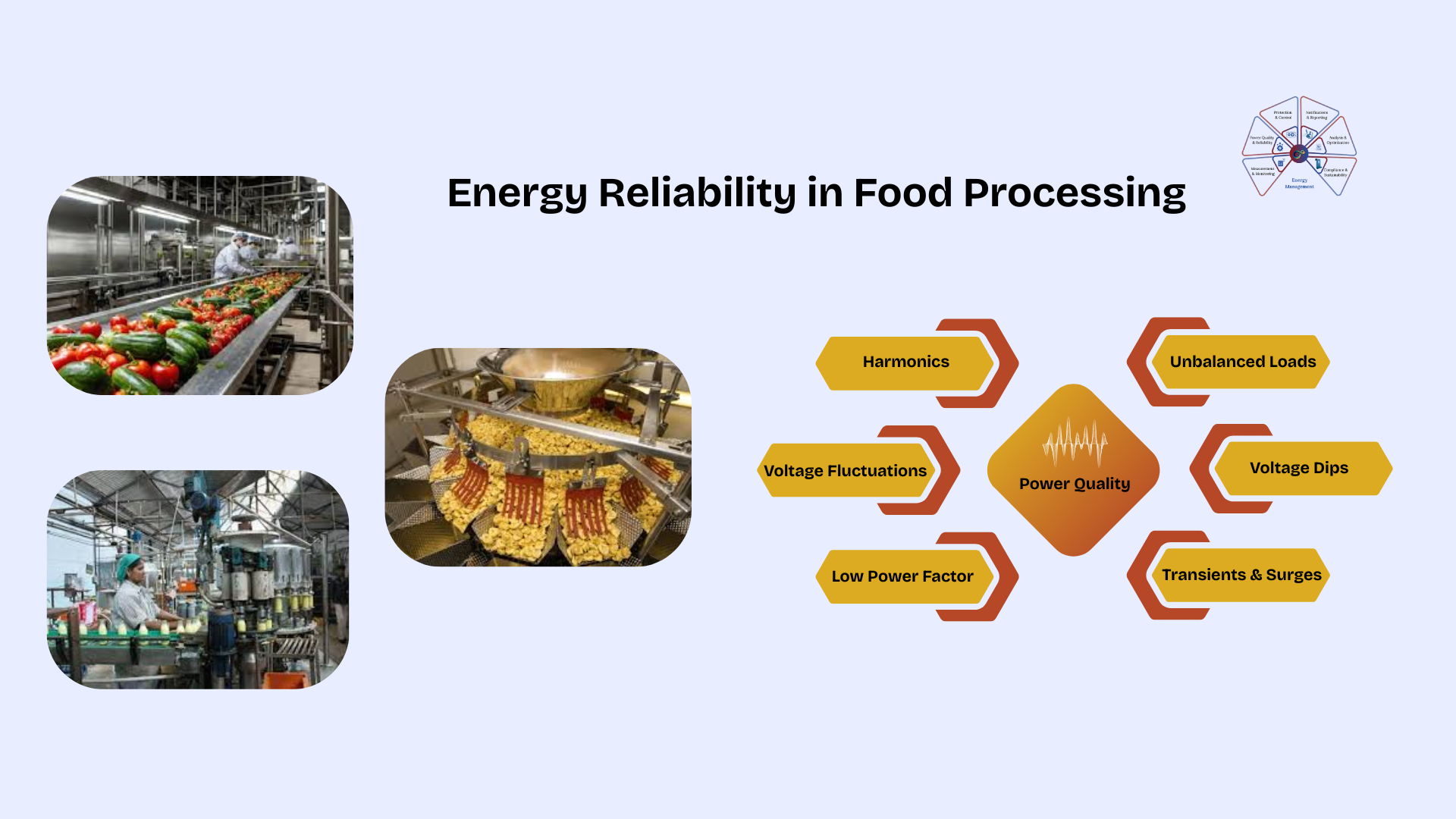

From Voltage Sags to OEE Drops: Understanding Energy Reliability in Food Processing

In a mid-sized food processing plant in the Delhi NCR region, the maintenance team had begun noticing something strange. Despite no major machinery failures, the Overall Equipment Effectiveness (OEE) was...

Power Quality in Steel Fabrication: Hidden Losses That Hurt OEE and Reliability

In a steel fabrication unit near Hapur, the rhythmic hum of welding machines and the precise movements of CNC cutters define productivity. The plant runs multiple MIG/TIG welding sets, plasma...

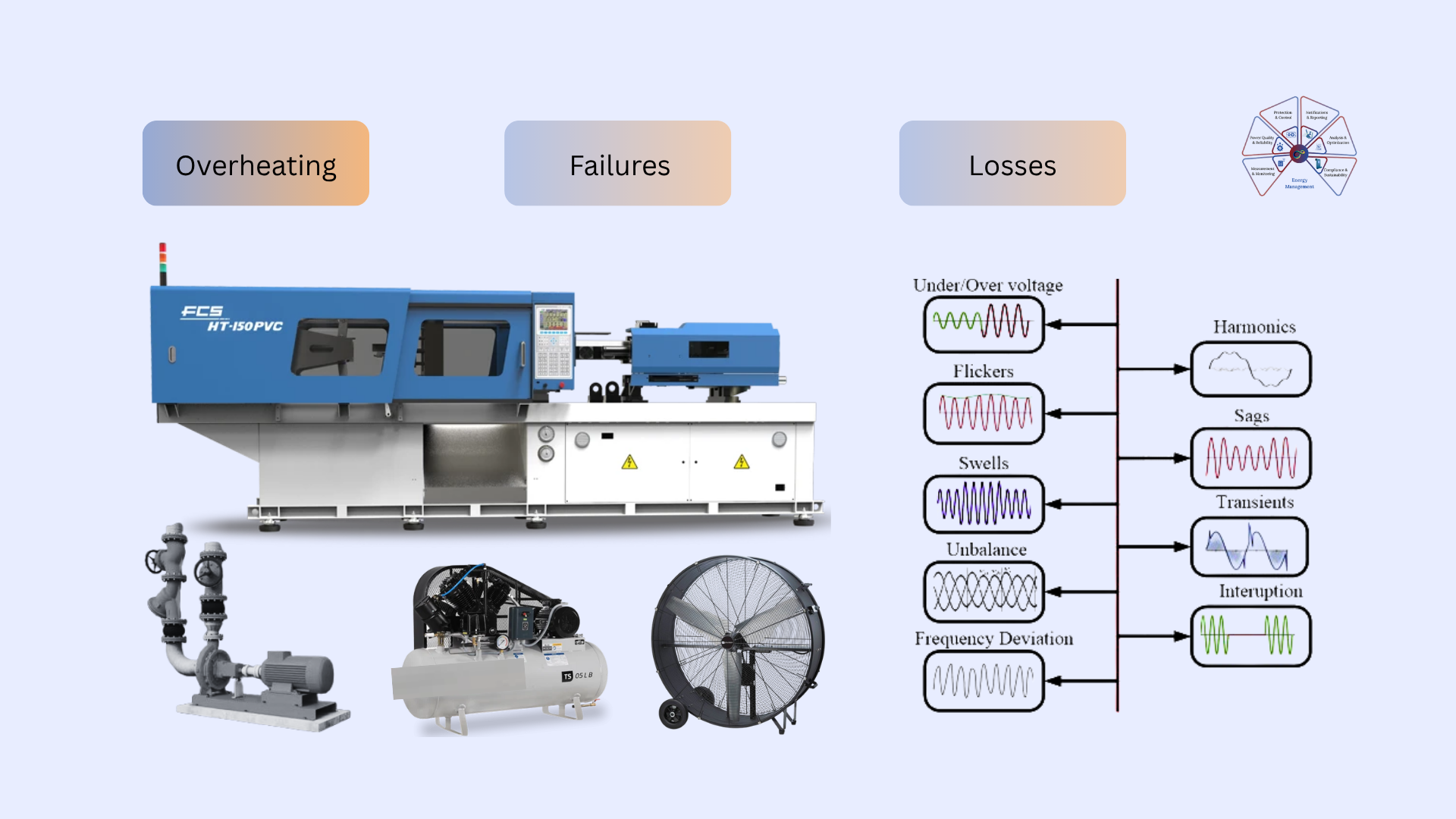

Reactive vs Proactive Maintenance in Plastic Molding Unit: Turning Power Quality Data into Maintenance Intelligence

In a plastic moulding unit in the Delhi NCR region, the maintenance team had earned a reputation for their agility and problem-solving skills. Whenever a machine tripped or a circuit...

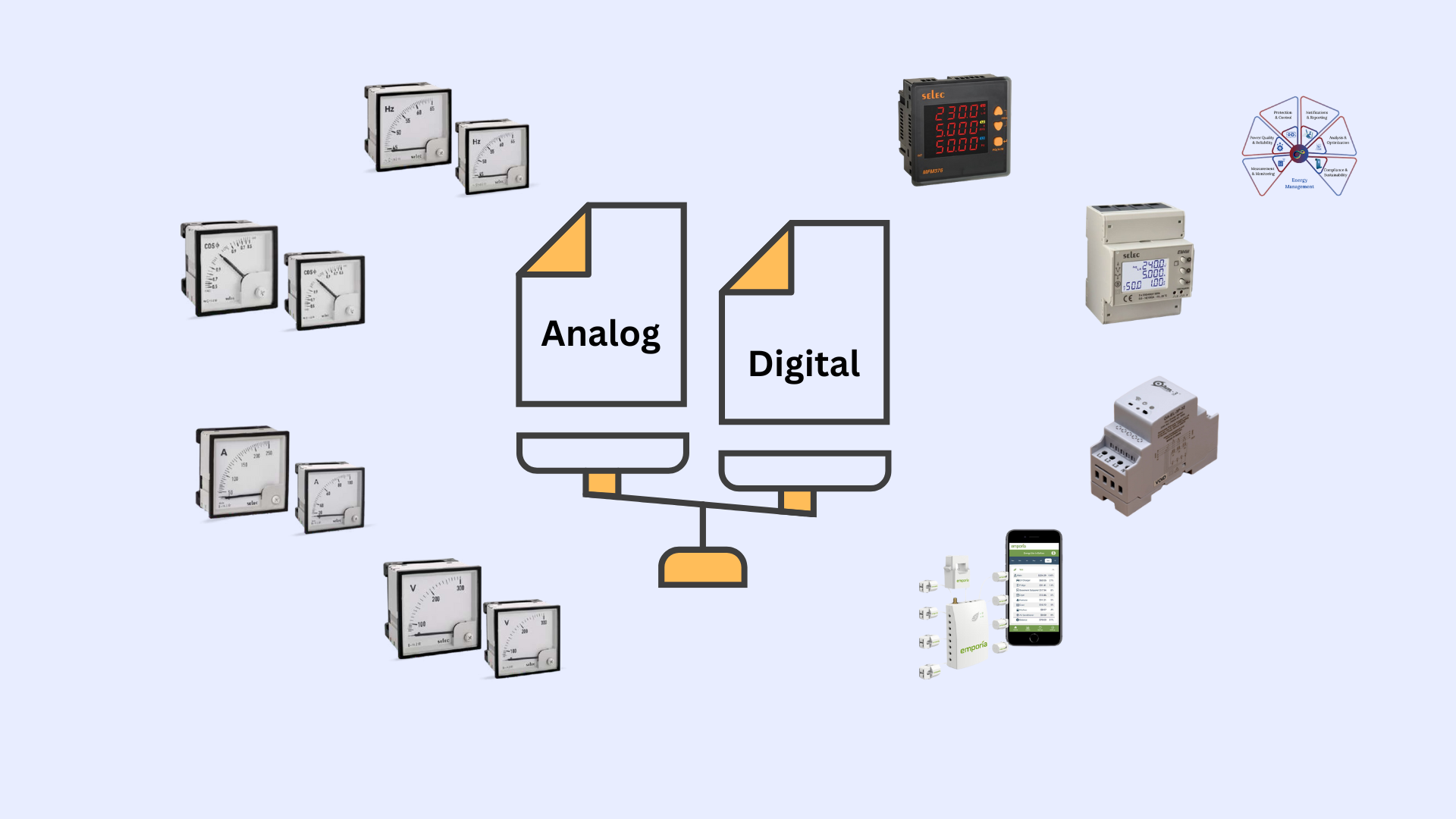

From Analog Panel Meters to Digital Monitoring: Why the Shift is Inevitable

For decades, analog panel meters were the backbone of electrical monitoring in factories, commercial buildings, and utility installations. Whether it was a simple voltmeter or an ammeter with a moving...

Managing Power Quality in Factories: Essential FAQs for O&M Teams

During a recent technical discussion with an MSME user in western Uttar Pradesh- the Maintenance Head, Plant General Manager, Purchase Manager, and a group of maintenance engineers had gathered in...

When Voltage Dips Hit Production: How an MSME Fertilizer Plant Safeguarded Its Operations

In western Uttar Pradesh, a mid-sized fertilizer manufacturer had built its reputation on timely supply to local farmers. The factory’s operations ran around the clock, supported by a mix of...

Managing Harmonics, Protecting Equipment: A Manufacturing Unit’s Success Story

In the middle of a busy production week, a mid-sized manufacturing unit faced a crisis that was becoming far too familiar. Their electronic drives, automation controllers, and LED lighting systems...

The Night Shift Mystery: How a Textile Unit Found a Hidden 10-12% Energy Drain

In a mid-sized textile unit in Surat, India, the maintenance manager had a nagging feeling: the electricity bills seemed out of proportion to production output. On paper, everything appeared in...

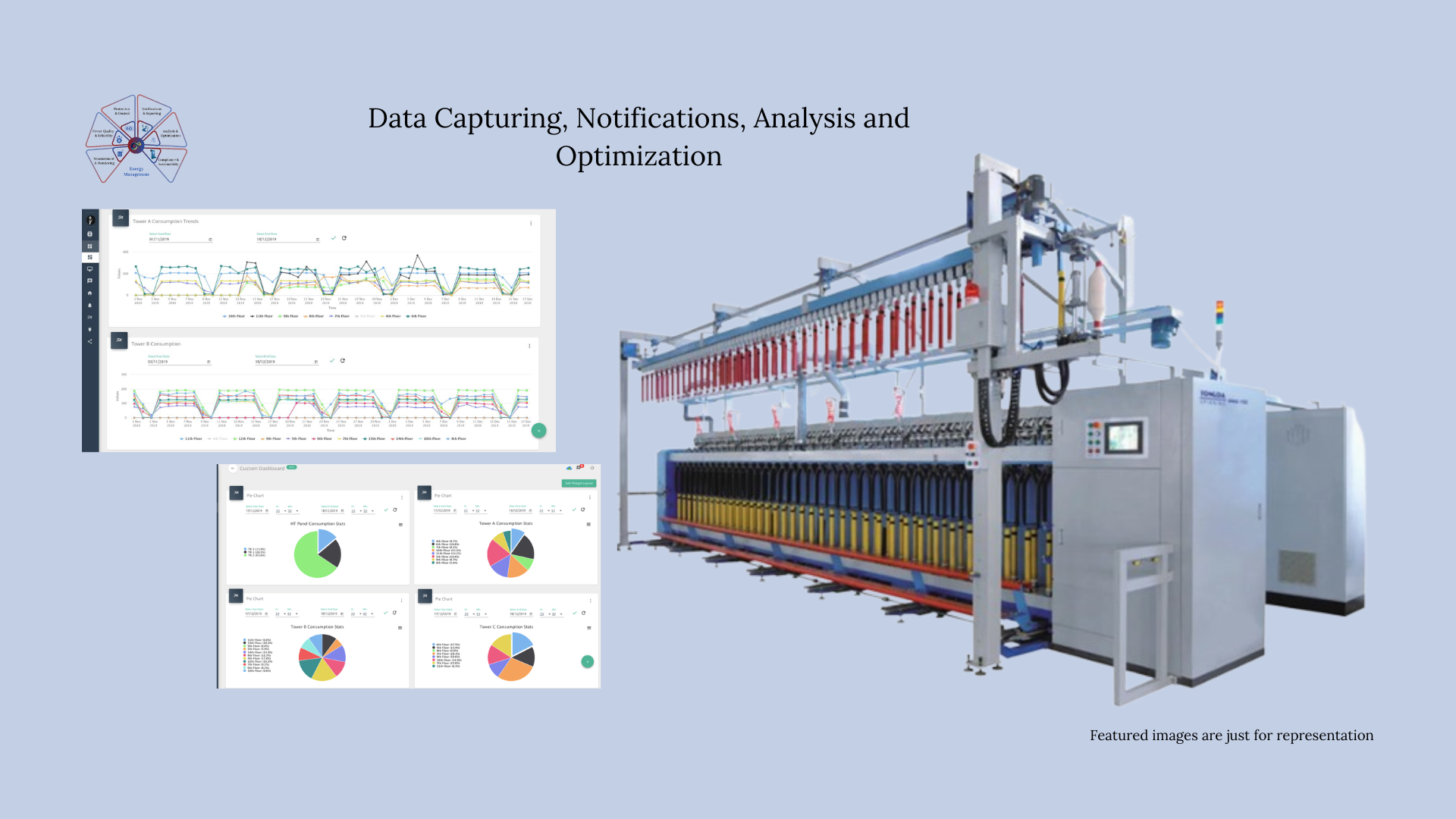

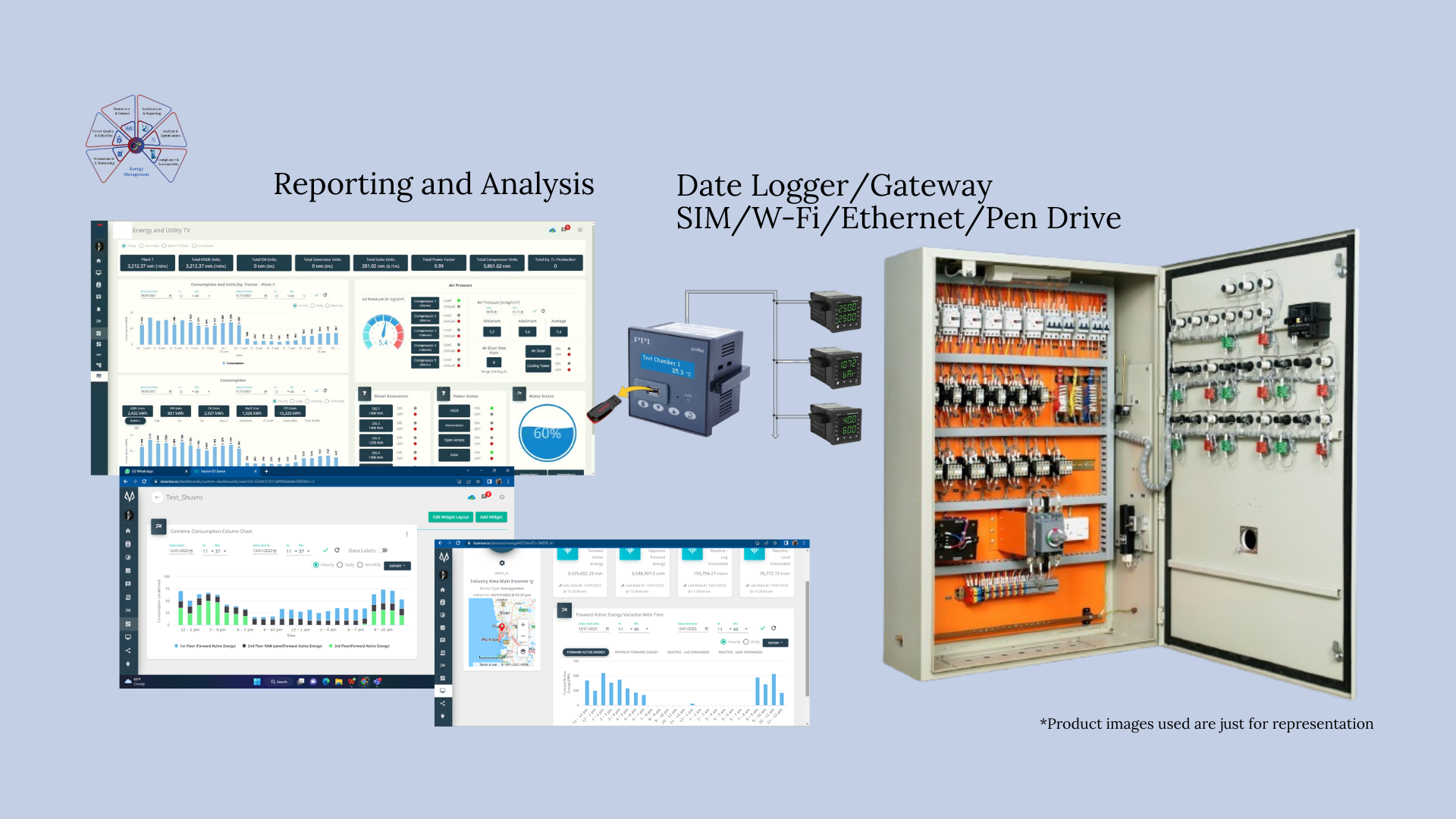

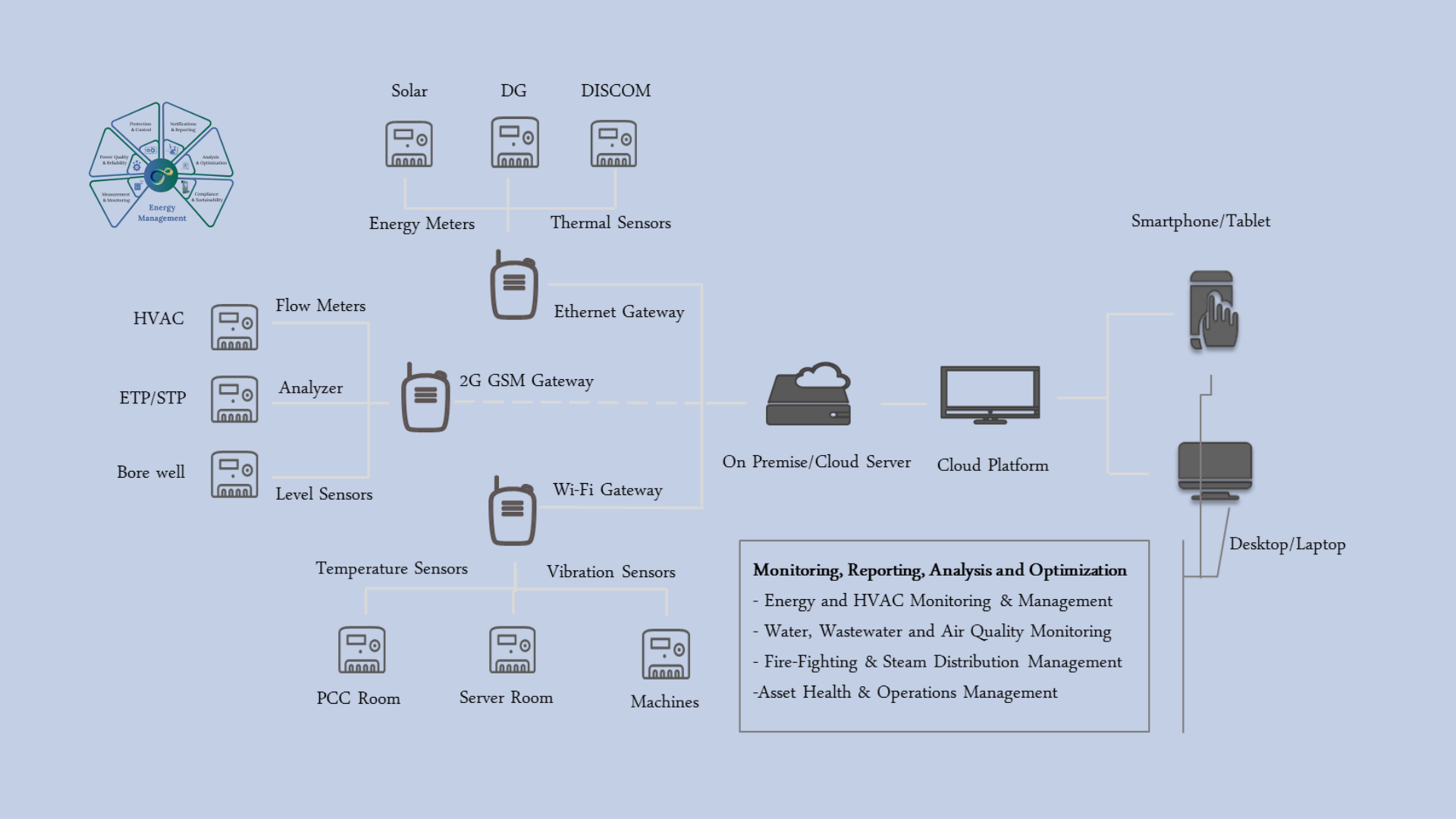

From Blind Spots to Insights: Building Energy Visibility in Mid-sized Manufacturing Units

When Meters Fail to Deliver Real Insights

Most manufacturing units start their energy management journey with energy meters (EM) or multifunction meters (MFMs). These devices display voltage, current, power factor, and...

Enhance Plant Reliability: Turning Maintenance Data into Actionable Results

At Intelliware, we often work alongside maintenance managers and technical staff in small to mid-sized industries. Unlike large corporates with dedicated departments, these units typically rely on the owner or...

Stopping Repeat Motor Failures: Lessons from a Plant Maintenance Team

At Intelliware, we often work alongside maintenance managers who share the realities of keeping equipment running day after day. Recently, one of our client’s teams faced a frustrating problem: motors...

From Outages to Power Quality Issues: How We Ensured Seamless Switching and Protected Critical Loads

In our facility, every second of downtime counts. We manage multiple production lines, sensitive control systems, and a variety of auxiliary equipment that must stay operational. Like most industrial setups...

From Costs to Carbon: Why Energy Monitoring is Now Essential for India’s Retail Chains

Modern retail chains aren’t just selling products — they’re running energy-intensive networks. Monitoring consumption across these facilities is no longer optional — it’s critical for cost control, operational efficiency, and...

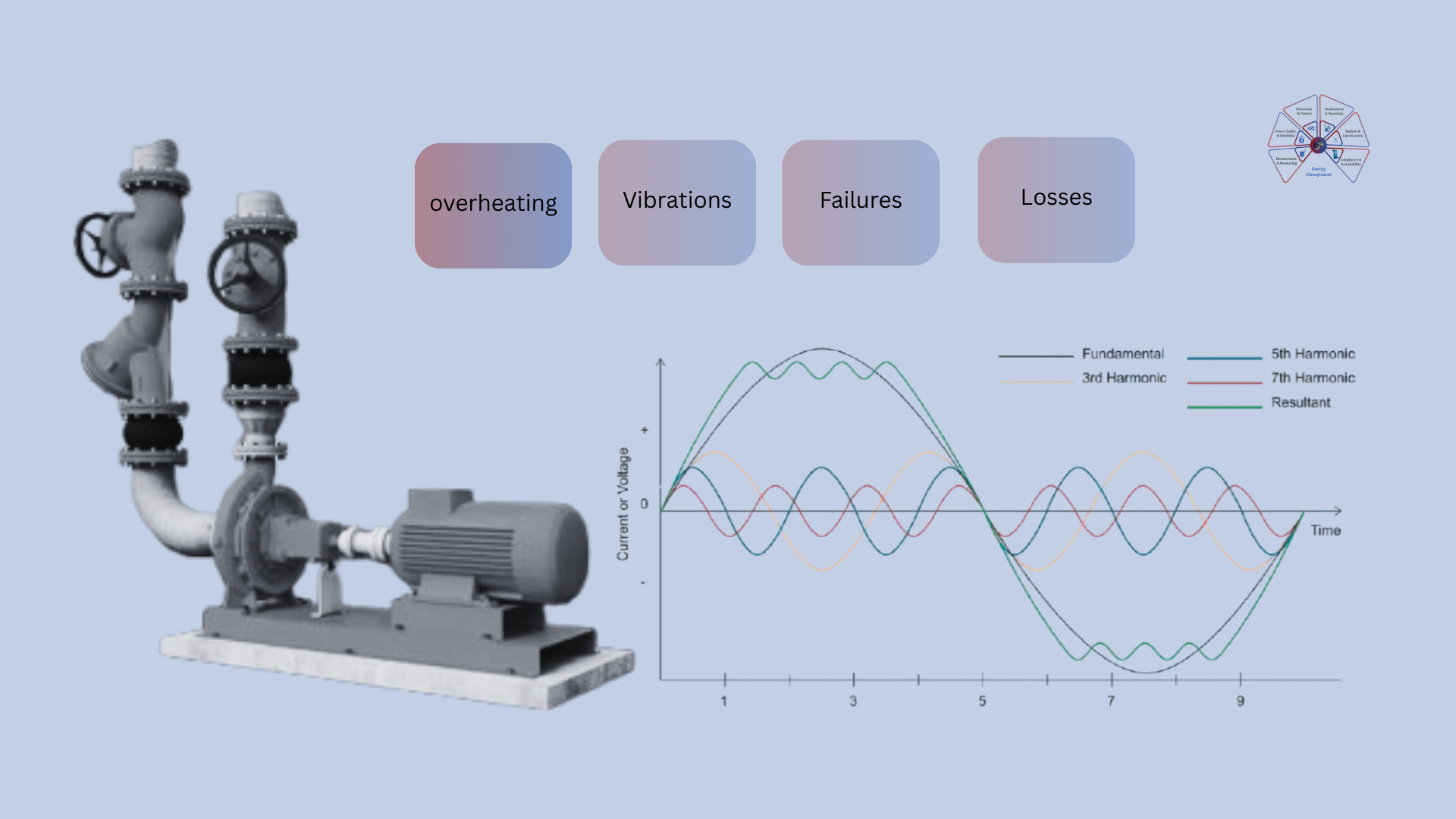

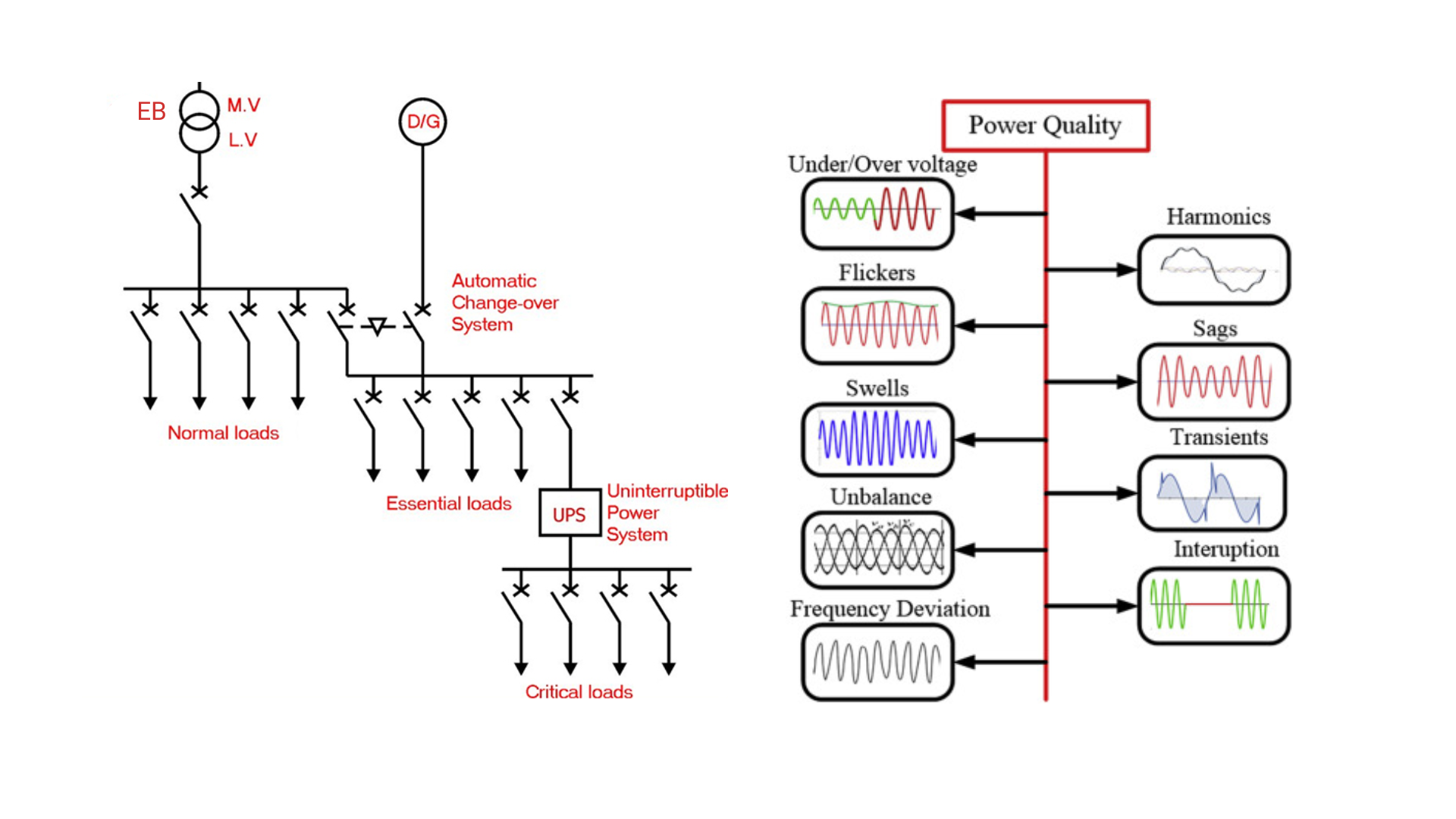

Understanding and Managing Power Quality in Industrial Systems

In today’s industrial environments, where automation, sensitive electronics, and high-energy processes coexist, power quality is no longer just a utility-side concern — it's a frontline operational issue.

Unexpected tripping, overheating, capacitor...

Managing Water Scaling and Algae Formation in Cement Plants – A Sustainable Approach with Swachh Paani

Water plays a critical role in cement manufacturing. From dust suppression and clinker cooling to slurry transfer and air conditioning, water is a key utility resource. However, the presence of...