Managing Harmonics, Protecting Equipment: A Manufacturing Unit’s Success Story

In the middle of a busy production week, a mid-sized manufacturing unit faced a crisis that was becoming far too familiar. Their electronic drives, automation controllers, and LED lighting systems were failing—again.

The maintenance manager had already replaced a batch of variable frequency drives (VFDs) just six months earlier, and now the new ones were showing erratic behavior. Motors tripped without reason, LED panels flickered and blackened, and sensitive control circuits overheated.

At first glance, it seemed like a quality issue with the suppliers. The purchase manager even called the VFD vendor demanding answers:

“We just bought these drives six months ago. Why are they failing again? Is this your product’s fault?”

The supplier, after reviewing the complaint, pushed back politely:

“Sir, our equipment is tested and certified. The failures you describe are consistent with poor power quality at site—especially harmonics. We recommend you check the electrical environment before holding the product responsible.”

This exchange left both teams puzzled. The factory was paying its electricity bills on time, their contracted load was within limits, and routine maintenance was being carried out. So why were electronics failing at such a high rate?

That’s when the maintenance manager decided it was time to dig deeper.

The Challenge – An Unseen Enemy in the Power System

The factory’s operations relied heavily on modern electronics:

- Variable Frequency Drives (VFDs) to regulate motors and save energy

- PLCs and automation systems for process control

- LED lighting to reduce utility bills

- Sensitive test equipment for quality control

Yet, these very devices seemed to be failing more often than traditional induction motors or heavy machinery.

Key challenges they faced:

- Unexplained failures: Electronics failed prematurely, often before their expected lifecycle.

- Increased downtime: Replacements and repairs caused production stoppages.

- Hidden costs: Frequent spares procurement added to the purchase manager’s headache.

- Blame game: Suppliers pointed to power quality, while internal teams suspected product defects.

What nobody realized immediately was that the culprit was not the devices—but the electrical environment itself. Harmonics were quietly eating into equipment life.

Why It Mattered – Business & Technical Impact

From a business standpoint, the situation was unsustainable. The finance manager flagged rising expenses on repairs, replacements, and unplanned downtime.

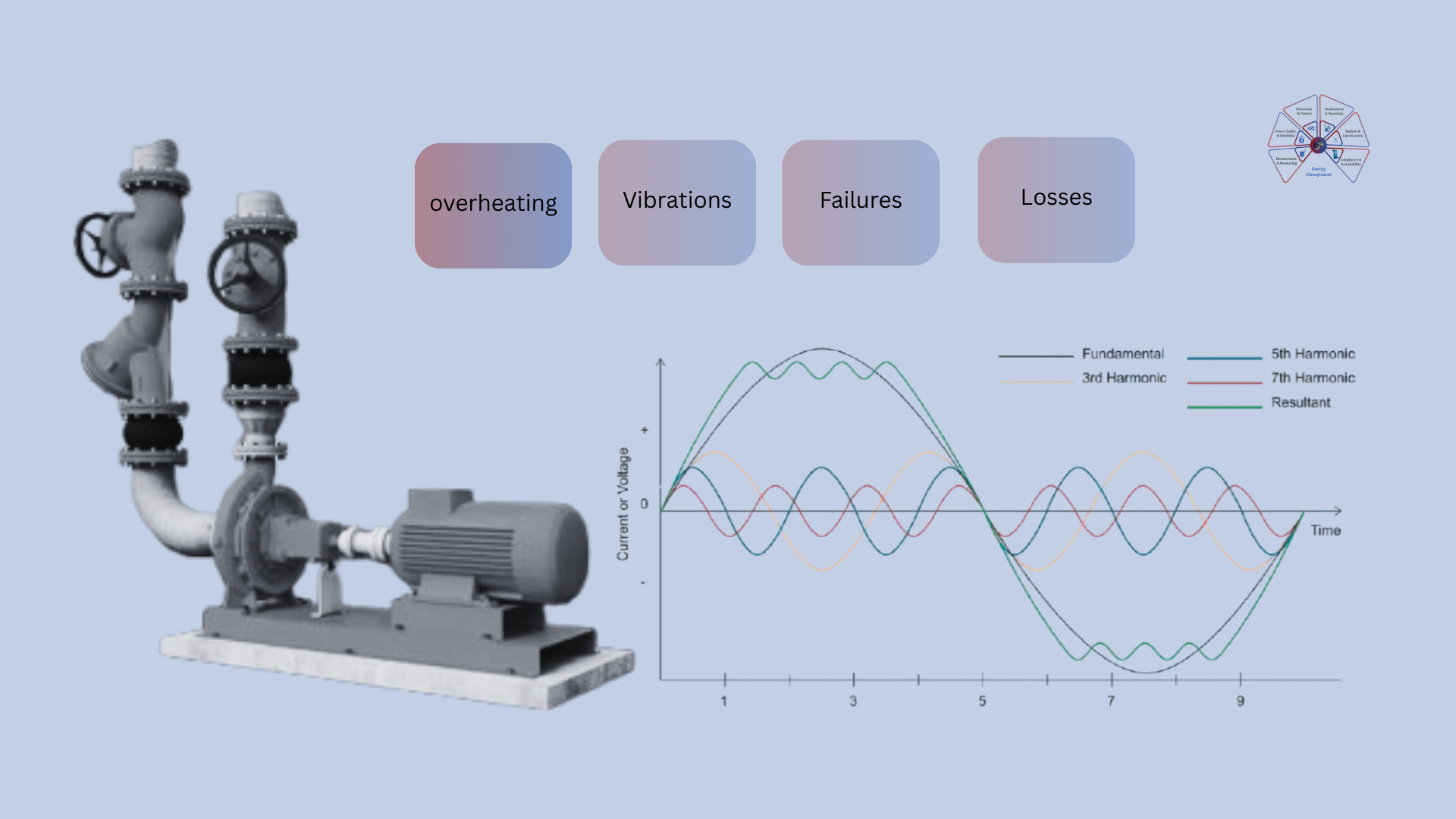

From a technical standpoint, the maintenance team realized that harmonics were distorting the power system. Non-linear loads (like VFDs, UPS systems, and LED drivers) were introducing harmonic currents, which caused:

- Overheating of cables and transformers

- Distorted voltage waveforms that stressed sensitive electronics

- False tripping of protection systems

- Increased energy consumption without obvious explanation

This wasn’t just about equipment life. It was about:

- OEE (Overall Equipment Effectiveness): Availability dropped because machines failed unexpectedly.

- Performance losses: Drives and controllers did not run at optimal efficiency.

- Quality issues: In some cases, process control errors led to product rejections.

The problem was both technical and financial—and it needed a structured approach.

The Blind Spot – Why Harmonics Stayed Hidden

Harmonics are not like a motor breakdown you can hear or see. They are invisible distortions in the electrical waveform. On the monthly EB bill, there was no line item called “harmonics penalty.”

Without proper monitoring, the plant had:

- No visibility into the level of distortion (THD – Total Harmonic Distortion).

- No linkage between equipment failures and power quality.

- No data to convince management or suppliers.

The maintenance team knew something was wrong, but without evidence, their concerns were dismissed as routine wear and tear.

The Turning Point – Engaging with Intelliware

When Intelliware connected with the plant, the focus was on creating clarity rather than rushing into corrective actions. Power quality monitoring was introduced as the first step, helping the team capture real conditions on the shop floor. This visibility ensured that any future investments- whether harmonic filters, load balancing measures, or equipment upgrades-would be precise and justified.

The maintenance manager also recognized the value of starting with data. By installing power quality meters, the team could track distortion levels, voltage fluctuations, and their impact on sensitive loads. With Intelliware’s support, the factory moved ahead with a structured monitoring approach, keeping solutions aligned with actual evidence instead of assumptions.

This simple but structured monitoring exercise changed the perceptions. For the first time, data showed that during certain production runs—especially when multiple drives and LED banks operated simultaneously—THD levels spiked to dangerous levels (above 15%).

Suddenly, the root cause was visible, undeniable, and measurable.

From Data to Action – Strategy for Mitigation

Once harmonics were confirmed, the factory had to act. But rather than jumping to a one-size-fits-all solution, Intelliware worked with the maintenance and purchase managers to develop a phased, ROI-based plan.

Actions taken:

- Load analysis: Identified which feeders and processes generated the most harmonics.

- Selective filtering: Installed active filters where harmonic levels exceeded thresholds.

- Improved cabling practices: Re-routed and sized cables to minimize heating.

- Procurement specifications: Worked with the purchase manager to update vendor requirements, ensuring future drives and UPS systems were compliant with harmonic standards (IEEE 519).

This meant the factory wasn’t just solving today’s failures—they were building resilience for tomorrow.

Results Achieved – From Failures to Stability

The outcomes were tangible within weeks:

- Electronic failures dropped by over 70% in the first quarter.

- Maintenance costs reduced, as fewer spares were needed.

- Availability improved, directly contributing to higher OEE.

- Energy losses reduced, as harmonics-related heating was minimized.

- Confidence restored, with purchase, maintenance, and finance finally aligned.

Most importantly, the purchase manager and suppliers now spoke the same language. Instead of blame games, discussions became data-driven:

- “Here’s the THD trend before and after filtering.”

- “Here’s how much equipment life has improved.”

- “Here’s the ROI from reduced downtime and spares.”

Broader Lessons for Maintenance Managers

This success story carries lessons for every maintenance manager and HOD:

- Harmonics are invisible but costly. Without monitoring, they eat away at reliability and efficiency.

- Electronics are more vulnerable. The more modern and efficient your systems, the more sensitive they are to poor power quality.

- OEE is directly linked. Availability, performance, and even product quality are impacted by harmonics.

- Cross-department collaboration is key. Maintenance, purchase, and finance must work together—not in silos.

- Data builds trust. Monitoring brings evidence, which turns arguments into decisions.

Turning Harmonic Challenges Into Action

“You can’t manage what you can’t see” and Harmonics are a perfect example. They remain hidden until they cause failures, but with the right visibility, they can be managed systematically.

If your facility is facing repeated electronic failures, unexplained tripping, or inflated replacement costs, the issue may not lie with the machines alone. Often, OEMs trace these failures back to power quality – and harmonics are a frequent culprit.

The right way forward is not guesswork, but structured dialogue.

- Start by reviewing recurring issues through a power-quality lens.

- Validate your observations with equipment OEMs and suppliers to establish the technical link.

- Engage with Intelliware for a focused discussion on proven mitigation solutions – from harmonic filters to monitoring tools – that directly address the root cause.

By connecting these dots, you move from frustration and recurring losses to a clear product-based solution that protects your equipment, stabilizes operations, and safeguards future investments.

📩 Connect with Intelliware team to explore how we can collaborate and help strengthening your plant’s reliability against harmonics.

- Call/SMS/WhatsApp: +91 8279921905

- email: contactus@intelliware.in

- Facebook: https://www.facebook.com/intelliware.in

- LinkedIn: https://linkedin.com/company/intelliware-in