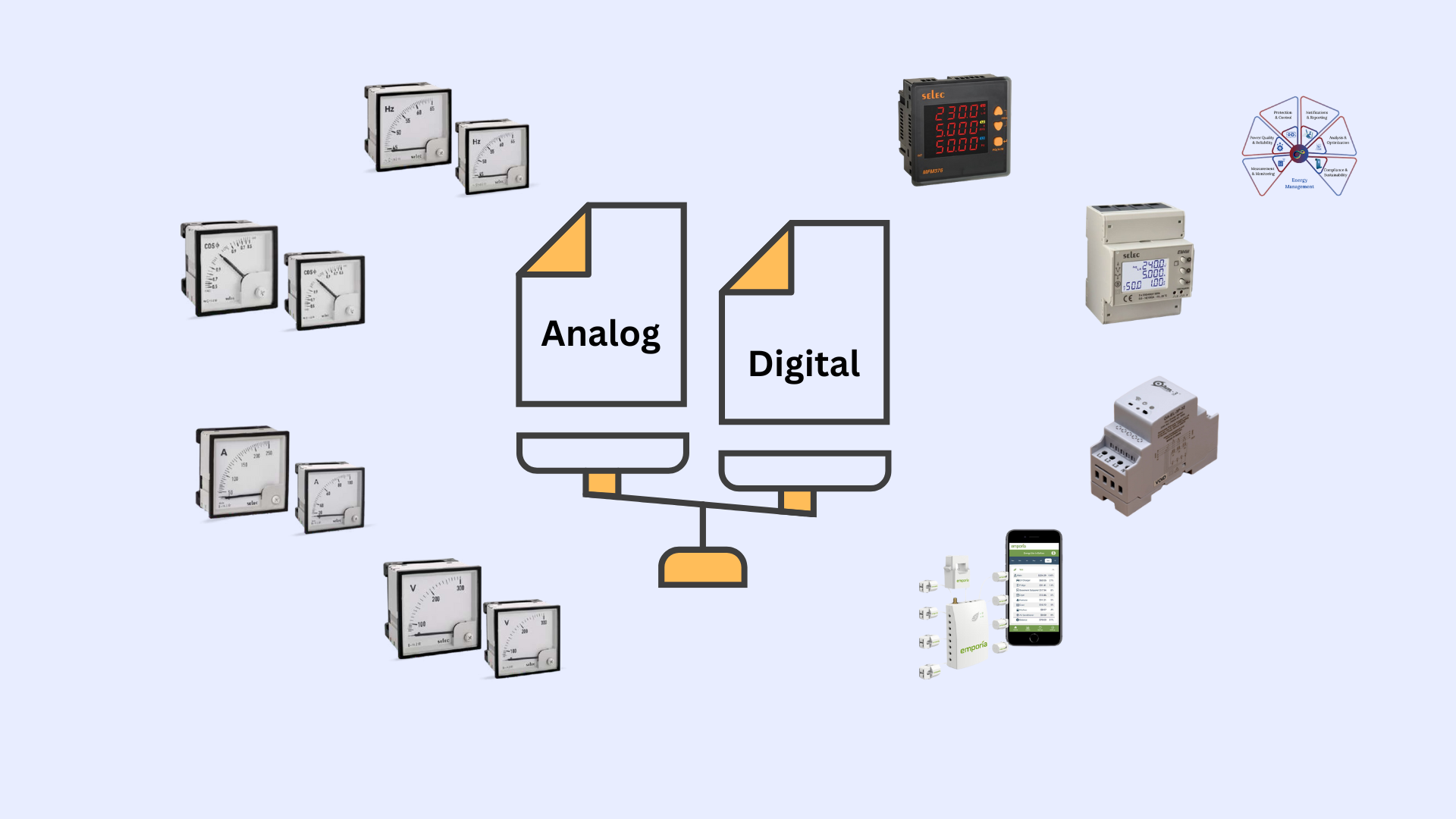

From Analog Panel Meters to Digital Monitoring: Why the Shift is Inevitable

For decades, analog panel meters were the backbone of electrical monitoring in factories, commercial buildings, and utility installations. Whether it was a simple voltmeter or an ammeter with a moving needle, these devices offered plant engineers a quick and affordable way to keep an eye on basic electrical parameters.

But as industries move toward efficiency, automation, and sustainability, analog meters are slowly becoming obsolete. Maintenance managers today are asking an important question: Are analog meters still enough for modern plants?

The answer lies in understanding both the limitations of analog meters and the advantages of digital monitoring solutions that are replacing them.

What Analog Panel Meters Offered

Analog meters were once the default choice because of their:

- Simplicity – easy to install and read with no configuration.

- Cost-effectiveness – very low initial investment.

- Ruggedness – mechanical meters could withstand tough conditions.

- Immediate visual feedback – a quick glance gave operators an approximate reading.

These features made them suitable in the past, when operations were less data-driven and monitoring was more about “is the system on or off” rather than detailed insights.

Limitations of Analog Panel Meters

However, in today’s world, analog meters face clear challenges:

- Limited to a single parameter per device (voltage, current, or frequency).

- No data logging – readings vanish the moment you look away.

- No integration with SCADA, EMS, or digital dashboards.

- Lower accuracy compared to modern industry standards.

- Susceptible to human error in manual reading and reporting.

- High maintenance needs due to mechanical wear and tear.

Simply put: analog meters tell you what’s happening now, but not why it happened, how often it happens, or what it costs you.

The Rise of Digital Monitoring Solutions

Digital meters and multifunction monitoring devices have rapidly replaced analog meters across industries.

Key advantages of digital monitoring:

- Multi-parameter measurement – voltage, current, frequency, power factor, kWh, harmonics, all in one device.

- High accuracy (Class 0.2 or 0.5) – essential for billing and compliance.

- Event logging & alarms – capture disturbances and deviations in real-time.

- Data communication – Modbus/RS485, Ethernet, or even IoT-based connectivity.

- Integration with EMS/BMS – enabling central dashboards and reports.

- Compact design – one digital MFM can replace 6–8 analog meters.

For maintenance managers, this means fewer devices, more data, and real-time visibility. You can review latest digital monitoring solutions on the following webpage: Energy and Multiparameter Measurement and Reporting

Analog vs Digital: A Quick Comparison

| Feature | Analog Meter | Digital Monitoring Device |

|---|---|---|

| Parameters | Single only | Multi-parameter |

| Accuracy | Moderate | High (Class 0.2 / 0.5) |

| Data logging | Not possible | In-built / Cloud-enabled |

| Integration with SCADA | Not possible | Native support |

| Human error | High | Minimal (digital output) |

| Maintenance | Regular calibration | Low |

Beyond Digital Meters: Advanced Monitoring Systems

The transition doesn’t stop at digital multifunction meters. Today’s facilities are also adopting:

- Energy Management Systems (EMS) – centralized platforms to track, analyze, and optimize consumption.

- IoT-based devices – enabling remote access, predictive alerts, and mobile dashboards.

- Power quality analyzers – for diagnosing harmonics, transients, and voltage dips.

- Smart sensors and controllers – extending monitoring to water pumps, HVAC systems, and motors.

These advanced systems transform raw electrical data into actionable insights for efficiency, safety, and sustainability.

Transition Path for Maintenance Teams

If your facility still has analog meters, here’s a practical roadmap:

- Identify critical feeders where analog meters are installed.

- Replace with digital MFMs that can measure multiple parameters.

- Connect meters to SCADA/EMS for centralized monitoring.

- Upgrade gradually – start with incomers and high-load feeders, then extend to smaller panels.

- Train staff to interpret digital data and use reporting tools.

This phased approach ensures smooth adoption while delivering quick ROI through better energy visibility and reduced downtime.

Conclusion: The Future is Digital

Analog panel meters played their role well, but the shift toward digital and intelligent monitoring is now irreversible. With increasing demand for data-driven decision making, compliance, and sustainability, digital solutions provide:

- Accuracy → for billing and compliance.

- Visibility → real-time monitoring of critical parameters.

- Connectivity → integration with EMS and cloud platforms.

- Sustainability → optimizing energy and water usage, reducing carbon footprint.

For maintenance managers, the question isn’t if you should replace analog meters — but when. And the sooner you adopt digital solutions, the faster you benefit from reduced risks, improved efficiency, and a more sustainable future.

✅ Connect intelliware for the Solution

Looking to upgrade from analog to digital? Explore Intelliware’s portfolio of digital multifunction meters, energy monitoring solutions, and EMS platforms — designed to give maintenance teams real-time visibility and control.

👉 Contact us to learn how you can transition smoothly and unlock the full value of modern monitoring.

- Call/SMS/WhatsApp: +91 8279921905

- email: contactus@intelliware.in

- Facebook: https://www.facebook.com/intelliware.in

- LinkedIn: https://linkedin.com/company/intelliware-in