Enhance Plant Reliability: Turning Maintenance Data into Actionable Results

At Intelliware, we often work alongside maintenance managers and technical staff in small to mid-sized industries. Unlike large corporates with dedicated departments, these units typically rely on the owner or a trusted technical team member to make both operational and maintenance decisions.

Recently, one of our client’s facilities — a mid-sized manufacturing plant — faced an all-too-familiar problem: repeated unplanned downtime, inefficient equipment performance, and constant procurement run for spares.

1. The Trigger: A Familiar Struggle

The plant’s machines were not failing outright, but their performance was inconsistent. Motors ran hot, certain feeders tripped frequently, and the power factor penalties were eating into monthly bills. The team wasn’t spending every day fighting fires, but a significant share of their time was lost in inefficient practices and ad-hoc fixes.

What struck us was not the absence of maintenance — they did have basic practices and budgeting in place — but the lack of visibility, monitoring, and data to guide decisions.

2. The 80:20 Rule in Action

In line with the Pareto principle, we observed that nearly 80% of their recurring problems were caused by just 20% of factors. And remarkably, 90% of these 20% factors were simple tasks — like monitoring harmonics, checking current imbalance, or optimizing load transfers — that could have been addressed with the right instrumentation and visibility.

Instead of investing heavily in overhauls, the client needed smarter monitoring and control at key points.

3. Moving Beyond Firefighting: Maintenance Evolution

Every plant passes through stages:

- Reactive Maintenance – Fix it when it breaks.

- Preventive Maintenance – Schedule checks and servicing.

- Predictive Maintenance – Use condition data to predict failures.

- Reliability-Centered Maintenance (RCM) – Balance cost, risk, and performance for sustainable reliability.

Our client was hovering between reactive and preventive modes. Without real-time data, trend analysis, and automated reporting, they couldn’t progress to predictive or reliability-based approaches.

4. The Procurement Loop

Like most small and mid-sized units, this plant was regularly engaged in procurement activities — from relays to meters, spares to consumables. While they maintained some budget and stock, the inefficiency lay in repeat purchases caused by avoidable issues.

For instance, relays were being replaced not because of true failure, but because upstream power quality issues were never addressed. This “loop” kept inflating costs without solving root causes.

5. The Turning Point: Plant Intelligence Adoption

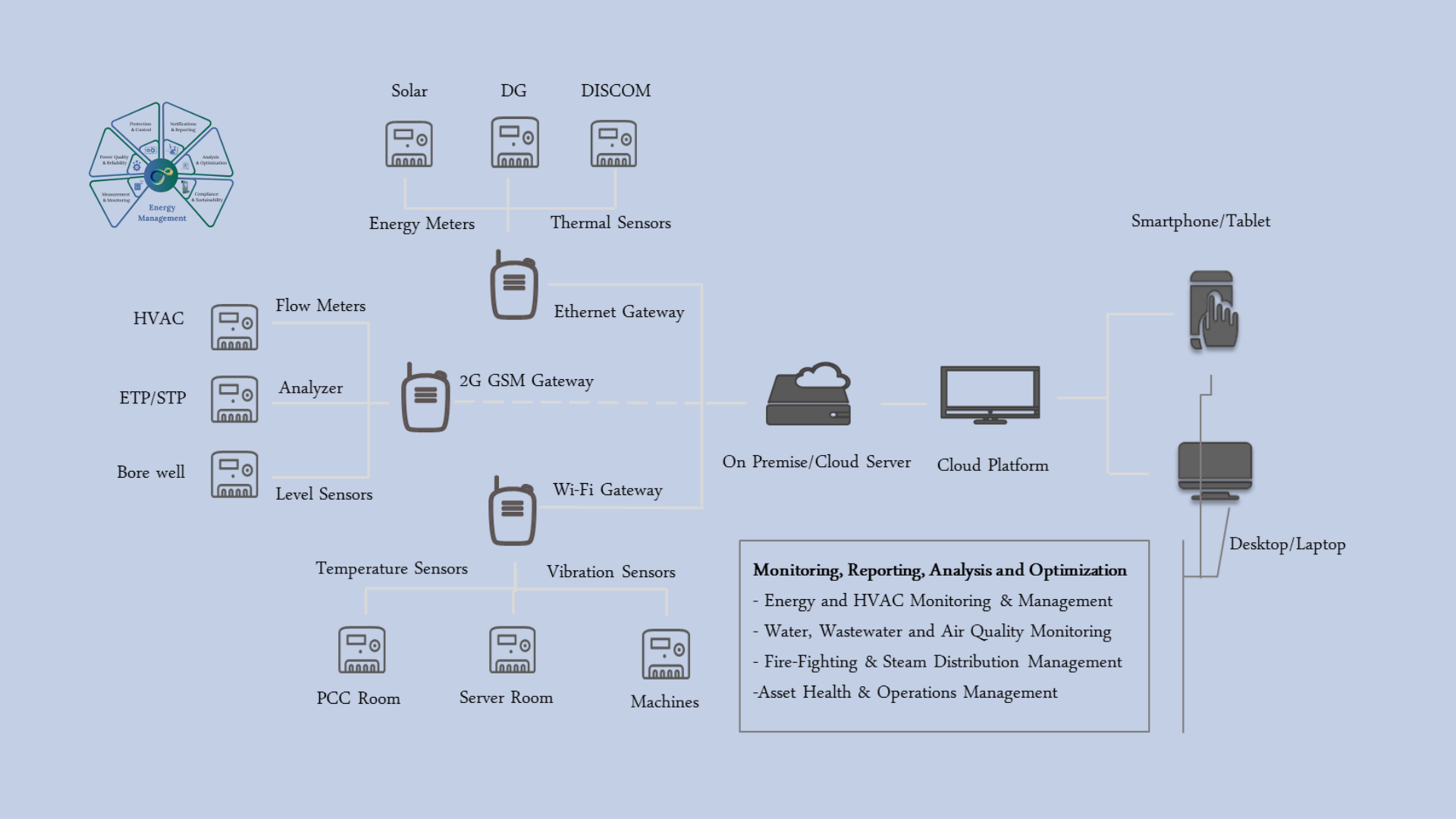

Here’s where change began. Instead of treating every issue as a standalone event, the client adopted basic monitoring solutions for power quality, load behavior, and equipment health.

- They installed multi-function meters on critical feeders.

- Configured alerts for unbalance and voltage dips.

- Started logging data to identify recurring patterns.

Suddenly, the plant had visibility. They were no longer making decisions in the dark — they had a dashboard to point out where and why inefficiencies were creeping in.

6. Results: From Decisions in the Dark to Data-Driven Control

Within months:

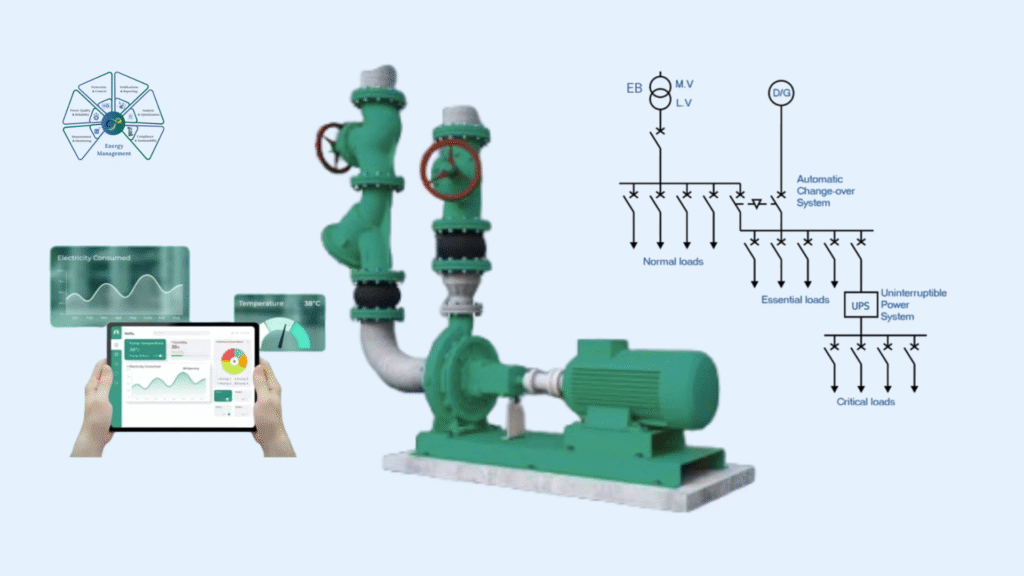

- Unnecessary relay replacements stopped, once the real cause (voltage dips during DG changeover) was identified.

- Power factor penalties reduced, thanks to timely monitoring and capacitor bank optimization.

- Procurement became sharper — instead of buying spares reactively, purchases were aligned with actual needs and preventive plans.

- Downtime reduced, not because breakdowns vanished overnight, but because the plant shifted from firefighting to controlled, planned interventions.

This was not about expensive automation or complex AI tools. It was about starting small with monitoring, building intelligence, and acting on real data.

7. Broader Impact: Efficiency and Sustainability

The hidden benefit? Sustainability. By controlling unplanned downtime, reducing energy wastage, and optimizing procurement, the plant lowered both its operational costs and its carbon footprint.

Reliability-centered maintenance isn’t just about machines — it directly supports sustainable operations, especially in a resource-sensitive market like India.

8. Intelliware’s Role

At Intelliware, we don’t just supply meters, relays, or controllers. We partner with plants to:

- Identify the 20% of factors causing 80% of issues.

- Introduce the right monitoring and protection tools.

- Enable transition from reactive firefighting to predictive and reliability-based maintenance.

- Support procurement with reliable sourcing and technical clarity.

For small and mid-sized units, this journey doesn’t require massive investments. It starts with smarter monitoring, better decisions, and reliable supplier partnerships.

Conclusion

The case above is not unique — it reflects the reality of many small and mid-sized units across India. Maintenance is already happening; what’s often missing is plant intelligence, data visibility, and reliable procurement support.

As this unit continues its journey towards reliability, the management is already evaluating the next steps: improving power quality, strengthening protection and control systems, and gradually introducing automation for smarter decision-making. Solutions such as Automatic Transfer Switches (ATS), Automatic Changeover with Current Limiter (ACCL), and multifunction monitoring meters are natural extensions that not only protect assets but also prepare the plant for sustainable growth.

By applying the 80:20 rule, moving from reactive to reliability-based maintenance, and aligning with sustainability goals, plants can unlock efficiency, reduce costs, and improve reliability.

At Intelliware, we see this as the real opportunity – to walk with such organizations from basic monitoring to intelligent, future-ready operations.